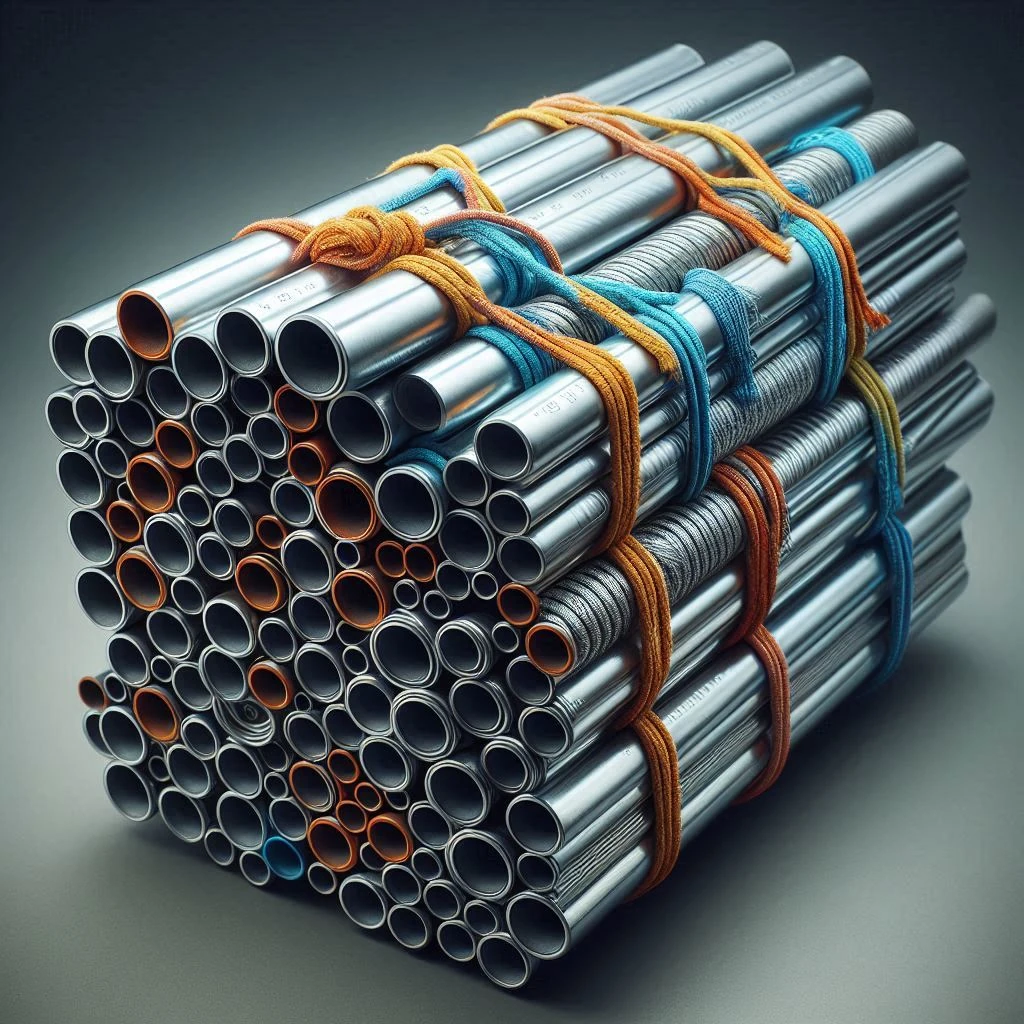

Technical specification of Hot Dip Galvanizing Pipe

| Specification | Details |

|---|---|

| Material | Galvanized Iron (GI) |

| Coating Process | Hot dip galvanizing |

| Standard Compliance | IS 1239 / BS 1387 / ASTM A53 |

| Pipe Length | Standard: 6 meters (custom lengths available) |

| Diameter Range | 20 mm to 200 mm (custom sizes available) |

| Wall Thickness | 2 mm to 10 mm |

| Pressure Rating | Up to 12 bar |

| Temperature Range | -20°C to 80°C |

| End Types | Plain, threaded, socketed |

| Coating Thickness | Typically 50 µm to 100 µm |

| Corrosion Resistance | Excellent, due to the zinc coating |

| Surface Finish | Smooth inner surface, uniform zinc coating |

| Application Areas | Water supply systems, drainage, construction, industrial piping |

| Chemical Properties | Zinc coating provides high resistance to acids and bases |

| Mechanical Properties | High tensile strength, impact resistance |

| Installation Requirements | Pipes should be installed with appropriate fittings and connectors, and protected from physical damage during installation |

| Maintenance | Regular inspection recommended to ensure coating integrity and performance |

| Certification | Certified for compliance with international and national standards |

Features

- The sophisticated hot dip galvanizing technique imparts a resilient zinc layer, delivering unparalleled resistance to environmental degradation and rust.

- Engineered to endure significant pressures and harsh conditions, these pipes ensure enduring reliability and robust performance.

- Perfectly suited for diverse uses, from intricate water management systems to demanding industrial applications, they guarantee dependable operation.

- Each pipe is meticulously manufactured to achieve a flawlessly smooth interior and precise dimensions, optimizing flow efficiency.

- Phoenix Corporation’s pipes meet stringent quality benchmarks, assuring exceptional durability and consistent, high-quality performance.

Reviews

There are no reviews yet.